Project Description

LDR Electric Heating Pressure Hot Water Boiler

0.12-0.58MW 0.2-0.7Mpa

Rated thermal power :0.06-0.53MW; Rated working pressure :0.7Mpa; Staturated water temperature :95℃;Return water temperature :70℃; Input Power :60-540KW; Rated voltage :3N AC 50Hz 380V; Industry :Foods, Garment, Taextile, Paper, Brewery, Ricemill, Dairy Products, Laundry, Poultry feed, Package, Plywood, Building material, Chemical, etc.Boiler furnace operates under pressure ,with double control of pressure and temperature ,no hidden trouble of safety .Hot water boiler –advanced touch screen controller, digital control system.

1.Hot water boiler with pressure –microcomputer controller, built-in backlight LCD screen display, clearly see operation of the boiler .All operations are easily accomplished by simply buttons.

2.High-power heating boiler uses step by step control heating group-it could start or stop working according to load change and significantly reduce the impact to the grid.The boiler could also manually open/stop heating section numbers, which convenient for adjusting boiler electrical heating power.

3.The system controls circulating pump base on boiler water temperature .Hot water boiler –during heating usage ,the circulation pump starts once boiler water reaches the upper limit and stops once boiler water lower than fixed lower limit .Hot water boiler –during bath usage ,the circulation pump stops once boiler water reaches the upper limit and starts once boiler water lower than fixed lower limit.”

4.Hot water boiler used for bath/living –inner part already been anticorrosive treated.Furnace body is not easily rusted &corrosion,long life usage and output hot water clean & sanitary .Using advanced centrifugal glass cotton fibre multilayer insulation, less heat loss,energy saving .Famous white color plate exquisite packaging, beautiful and corrosion resistance.

5.Hot water boiler –electric leakage protection , prevent dry burning/ low water level protection, furnace overheating protection, temperature sensor protection, power supply &voltage protection , heating component failure protection etc.”

Whole Picture Appreciation

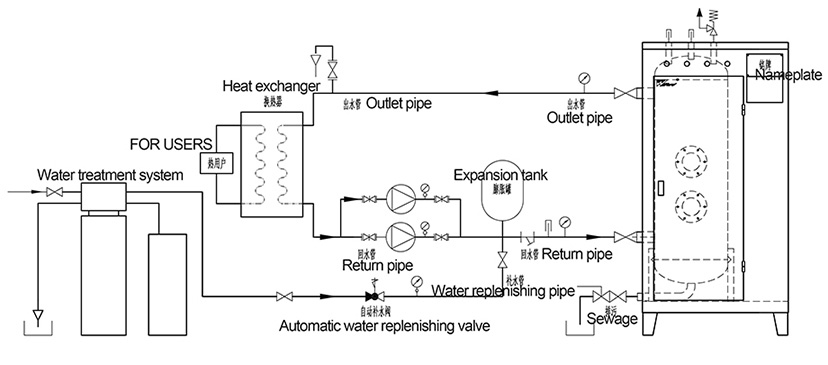

Product system Drawings

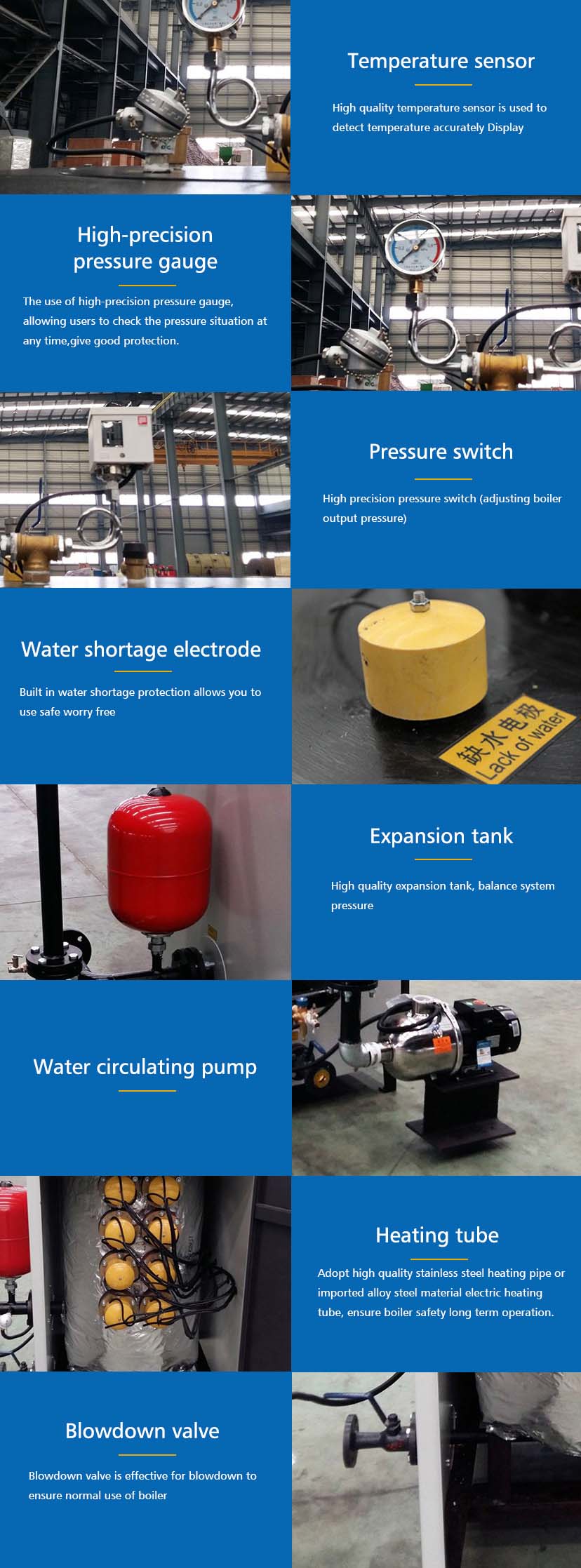

Product Detail Analysis

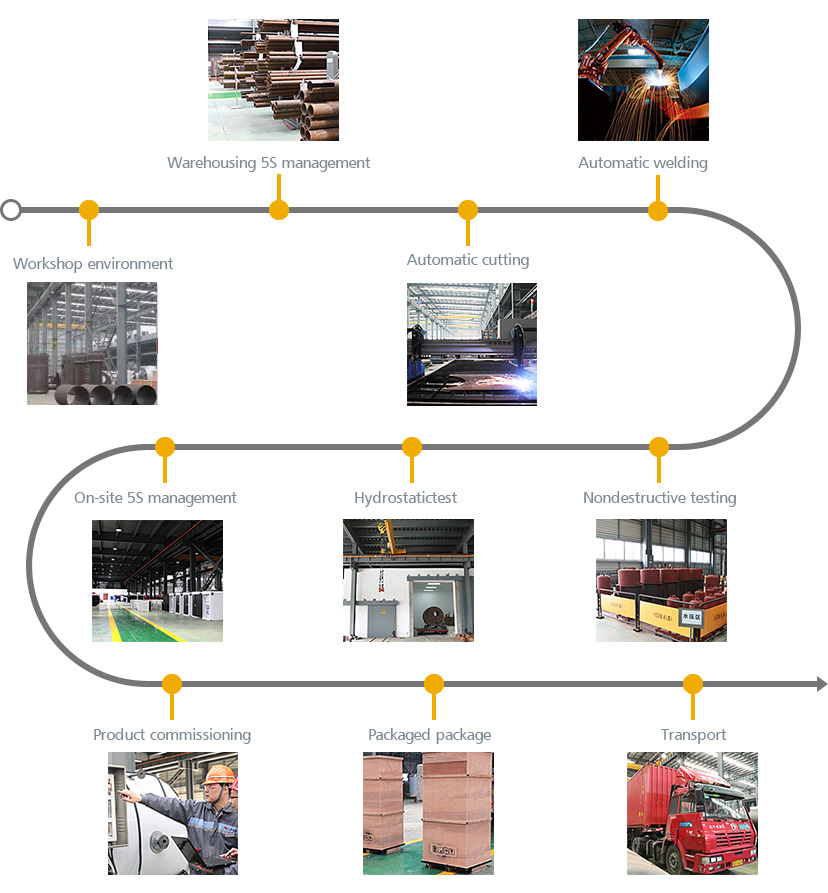

Technological Process

Our Customer

Our Services

For each user, we understand and analyze in detail their different production environment and the shortage of products in order to provide reasonable technical solutions and timely after-sales service. We attach great importance to the effective operation system of boiler products to provide customers with problem solutions, and send experienced engineers to the site to guide. The company has accumulated a wealth of on-site problem-solving experience, providing strong technical support and perfect after-sales service. User success is our success!

Company Information

Wilford company is specialized in manufacturing the medium and small sized boilers with high quality to solve the high energy efficiency requirements of customers in industrial and commercial fields for steam and heat sources. We supply the whole solution of boilers and boiler systems, reduce energy consumption, save operating costs for each plant, enhancing the environmental protection requirements.

Since 1998, the company are insisted on intelligent and lean production as the leading factor to ensure that each product is super safe and high quality. The fuel, gas and electric heating boilers have high technical content. The company has won many inventions, many high-tech products and new technology and new product awards. We regard the boiler’s efficiency index and extremely low nitrogen emission requirements as the main innovation objectives, Keep unremitting efforts in the environmental protection and energy saving of boilers.

Our products have obtained ASME, CE, SIGAPORE MOM, MALAYSIA DOSCH, AUSTRALIAN WORK SAFE, RUSSIA CU-TR and other certification, the local registration of various countries and other problems are very professional, we have a very strong service team, good service for each customer is our only pursuit!

| LDR Electric Heating Pressure Hot Water Boiler | |||||||||

| Type | LDR0.06-0.7-95/70 | LDR0.09-0.7-95/70 | LDR0.12-0.7-95/70 | LDR0.18-0.7-95/70 | LDR0.23-0.7-95/70 | LDR0.35-0.7-95/70 | LDR0.47-0.7-95/70 | LDR0.53-0.7-95/70 | |

| Project | Unit | ||||||||

| Rated working pressure | MPa | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Staturated water temperature/Reture water temperature | ℃ | 95/70 | 95/70 | 95/70 | 95/70 | 95/70 | 95/70 | 95/70 | 95/70 |

| Input Power | KW | 60 | 90 | 120 | 180 | 240 | 360 | 480 | 540 |

| Input current | A | 90 | 135 | 180 | 270 | 360 | 540 | 720 | 810 |

| Rated voltage | V | 3N AC 50Hz 380V | |||||||

| Power×Group | KW×P | 15×4 | 15×6 | 15×8 | 25×6+15×2 | 25×9+15 | 36×10 | 36×12+25×2 | 36×15 |

| aWater outlet diameter | DN | 50 | 50 | 50 | 50 | 50 | 80 | 80 | 80 |

| b Water return diameter | DN | 50 | 50 | 50 | 50 | 50 | 80 | 80 | 80 |

| c Water inlet diameter | DN | 15 | 15 | 15 | 15 | 15 | 25 | 25 | 25 |

| d Blowoff Valve diameter | DN | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 40 |

| e Safety valve diameter | DN | 15 | 15 | 15 | 25 | 25 | 40 | 40 | 40 |

| Overall size | L mm | 750 | 750 | 750 | 1200 | 1200 | 1600 | 1600 | 1600 |

| W mm | 650 | 650 | 650 | 1100 | 1100 | 1200 | 1350 | 1350 | |

| H mm | 1380 | 1380 | 1380 | 1900 | 1900 | 2000 | 2200 | 2200 | |

| LDR0.53 and more ,the structure is seperated,with indepedent control cabinet. | A mm | – | – | – | – | – | 1200 | ||

| B mm | – | – | – | – | – | 600 | |||

| C mm | – | – | – | – | – | 1800 | |||

| Weight | kg | 180 | 200 | 235 | 485 | 525 | 620 | 710 | 820/1350 |

| (额定工作压力:0.2MPa为免检型承压热水锅炉(仅用自来水加压) Following are National inspection-free hot water boiler with pressure ( tap water pressure only ) | |||||||||

Q : Are you a factory or a trading company?

A : We are a 20-year-old industrial boiler factory , specializing in gas oil diesel electric fired boilers. Now we are one of leading industrial boiler manufacturers in China.

Q : What is the Warranty for the boilers?

A : Our steam boiler warranty is one year, During the warranty period, any parts damaged, you can get a new parts for free.

Q : How long should we wait for delivery?

A : Usually it will take about 35-45 days for pressured boilers, If you need to change the voltage or pressure, it need more time .

Q What about your payment term?

A : Usually it would be 30% deposit payment, 70% balance before delivery. We accept T/T, L/C and other payment way.

Contact Us

Address: No5,Nanyuan Road Economic Development Zone, Zhangjiagang

Tel: +86-512-5679 1900

Fax: +86-512-5869 8850

Email: [email protected]

WhatsApp: +86 136 0156 8070

WeChat: 136 0156 8070