Project Description

YY(Q)W Oil(gas)Fired Thermal Oil Boiler

600-6000KW 1-1.1Mpa

Rated thermal power :600-6000KW; Heating efficiency :90/92% ;The water temperature :95/115℃;Design pressure :1/1.1Mpa; Medium highest temperature :350℃; Fuel :Natural gas, diesel oil, LPG, Pipeline gas, etc. YY(Q)W oil(gas)heating-conduction boiler makes heat carrier circulation through hot oil pump is fast mounted forced circulation oil (gas) fuel boiler. High heat efficiency ,special structure ,could keep total heat efficiency up to 100%.

YY(Q)W oil(gas)heating-conduction boiler makes heat carrier circulation through hot oil pump is fast mounted forced circulation oil (gas) fuel boiler.The heating surface structure is compact. Inside/middle/outside (or inside and out side ) closely-aligned round coils constitute the heating surface . Inside coil is radiation heating surface.Middle/outside coils as well as inside coils together from convection heating surface .Fuel burns in inside coils’ combustion chamber -combustion and heat release.After radiation heating surface absorbs most heat, high temperature flue gas enters the convection heating surface to transfer heat. Finally low temperature flue gas exports directly through chimney to atmosphere .

Product Features

1.High heat efficiency ,special structure ,could keep total heat efficiency up to 100%.

2.The control of the oil temperature will be concise within the range from -1°C to +1°C.Under low working pressure of 0.8Mpa ,boiler could achieve working temperature of 320°C.

3.There’s a connection for the inert gas on the front shroud and it could fill 3 times of the capacity of the furnace with inert gas within 15 minutes in case of emergency to protect it and thus extend the life span.

4.Fully shop-assembled ,save transportation cost and installation fees.

5.The boiler operates automatically and will get rid of misconduct .With a nuclear PLC ,the percentage will be adjusted automatically and the monitor will be ral time ,together with the chainining protection.

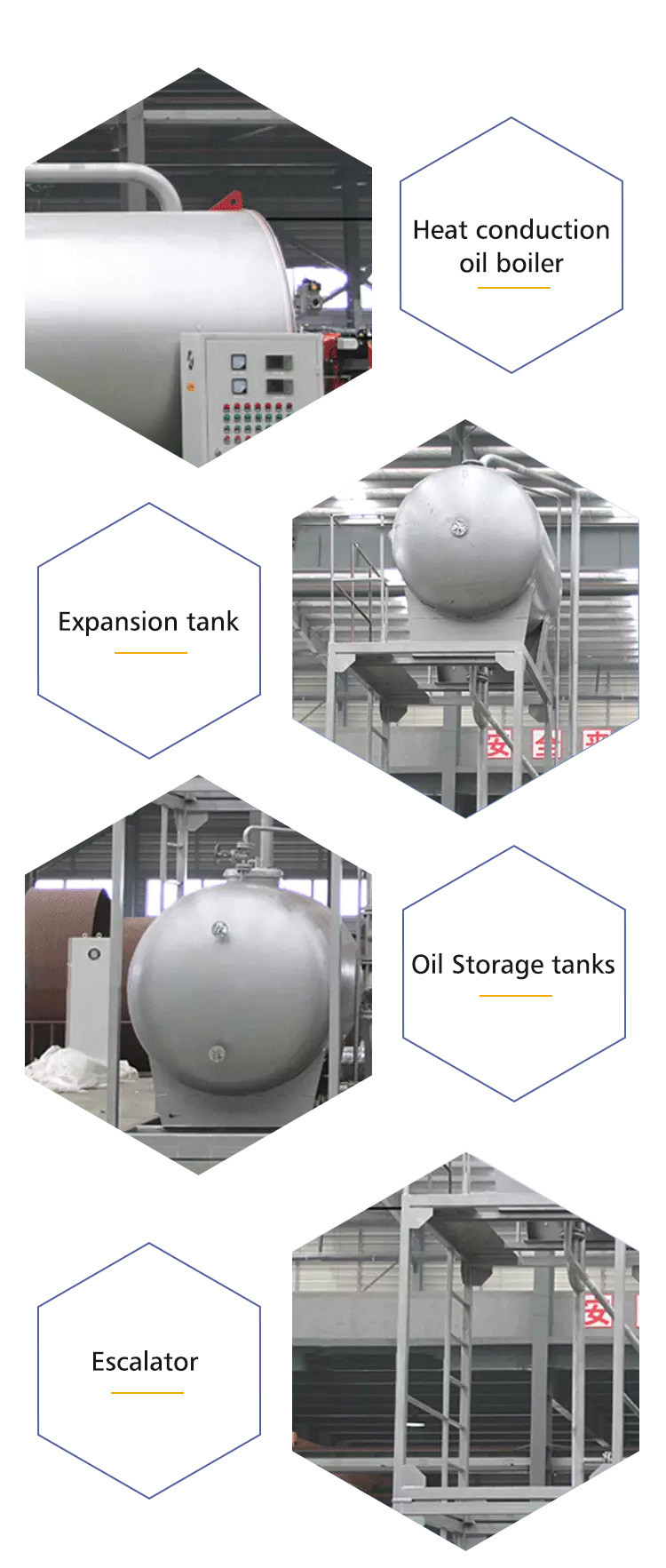

Whole Picture Appreciation

Product Detail Analysis

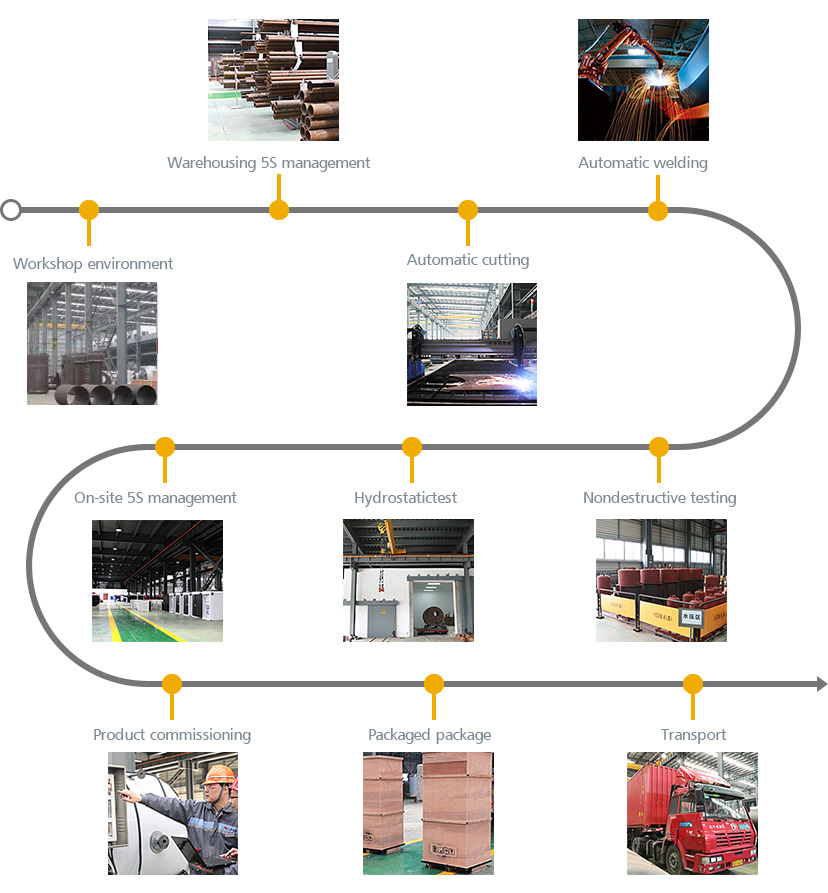

Technological Process

Our Customer

Our Services

For each user, we understand and analyze in detail their different production environment and the shortage of products in order to provide reasonable technical solutions and timely after-sales service. We attach great importance to the effective operation system of boiler products to provide customers with problem solutions, and send experienced engineers to the site to guide. The company has accumulated a wealth of on-site problem-solving experience, providing strong technical support and perfect after-sales service. User success is our success!

Company Information

Wilford company is specialized in manufacturing the medium and small sized boilers with high quality to solve the high energy efficiency requirements of customers in industrial and commercial fields for steam and heat sources. We supply the whole solution of boilers and boiler systems, reduce energy consumption, save operating costs for each plant, enhancing the environmental protection requirements.

Since 1998, the company are insisted on intelligent and lean production as the leading factor to ensure that each product is super safe and high quality. The fuel, gas and electric heating boilers have high technical content. The company has won many inventions, many high-tech products and new technology and new product awards. We regard the boiler’s efficiency index and extremely low nitrogen emission requirements as the main innovation objectives, Keep unremitting efforts in the environmental protection and energy saving of boilers.

Our products have obtained ASME, CE, SIGAPORE MOM, MALAYSIA DOSCH, AUSTRALIAN WORK SAFE, RUSSIA CU-TR and other certification, the local registration of various countries and other problems are very professional, we have a very strong service team, good service for each customer is our only pursuit!

| YY(Q)W Oil(gas)Fired Thermal Oil Boiler | |||||||||||

| Description | Unit | YY(Q)W-600-Y.Q | YY(Q)W-850-Y.Q | YY(Q)W-1200-Y.Q | YY(Q)W-1400-Y.Q | YY(Q)W-1800-Y.Q | YY(Q)W-2400-Y.Q | YY(Q)W-3500-Y.Q | YY(Q)W-4100-Y.Q | YY(Q)W-6000-Y.Q | |

| Rated thermal power (KW) | KW/10000kcal | 600/50 | 850/75 | 1200/100 | 1400/125 | 1800/150 | 2400/200 | 3500/300 | 4100/350 | 6000/500 | |

| Heating efficiency (≥%) | % | 90 | 90 | 90 | 92 | 92 | 92 | 92 | 92 | 92 | |

| Design pressure | Mpa | 1 | 1 | 1 | 1 | 1 | 1 | 1.1 | 1.1 | 1.1 | |

| Medium highest temperature | ℃ | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | |

| Medium capacity of boiler | m³ | 0.4 | 0.52 | 0.76 | 0.95 | 1.48 | 2.1 | 2.4 | 2.53 | 6.1 | |

| Medium circulation volume | m³/h | 80 | 80 | 100 | 100 | 160 | 200 | 200 | 200 | 300 | |

| DN of oil outlet | DN | 100 | 100 | 125 | 125 | 150 | 200 | 200 | 200 | 250 | |

| Whole system installed capacity | Oil | KW | 30 | 40 | 40 | 45 | 50 | 70 | 70 | 70 | 150 |

| Gas | KW | 30 | 40 | 40 | 45 | 50 | 70 | 70 | 70 | 150 | |

| Total weight of equipment | KG | 3530 | 4500 | 5600 | 6200 | 9500 | 10500 | 13500 | 16065 | 28850 | |

| External dimension | Length | mm | 3650 | 4100 | 5500 | 5700 | 5900 | 6500 | 8000 | 8200 | 9000 |

| Width | mm | 1500 | 1700 | 2100 | 2100 | 2100 | 2300 | 2400 | 2500 | 3200 | |

| Height | mm | 1870 | 2100 | 2400 | 2400 | 2550 | 2750 | 2900 | 3000 | 3600 | |

| Transport dimension | Length | mm | 3250 | 3800 | 4600 | 4850 | 5100 | 5800 | 6800 | 7200 | 7800 |

| Width | mm | 1500 | 1700 | 2100 | 2100 | 2100 | 2300 | 2400 | 2500 | 3200 | |

| Height | mm | 1870 | 2100 | 2400 | 2400 | 2550 | 2750 | 2900 | 3000 | 3600 | |

Q : Are you a factory or a trading company?

A : We are a 20-year-old industrial boiler factory , specializing in gas oil diesel electric fired boilers. Now we are one of leading industrial boiler manufacturers in China.

Q : What is the Warranty for the boilers?

A : Our steam boiler warranty is one year, During the warranty period, any parts damaged, you can get a new parts for free.

Q : How long should we wait for delivery?

A : Usually it will take about 35-45 days for pressured boilers, If you need to change the voltage or pressure, it need more time .

Q What about your payment term?

A : Usually it would be 30% deposit payment, 70% balance before delivery. We accept T/T, L/C and other payment way.

Contact Us

Address: No5,Nanyuan Road Economic Development Zone, Zhangjiagang

Tel: +86-512-5679 1900

Fax: +86-512-5869 8850

Email: [email protected]

WhatsApp: +86 136 0156 8070

WeChat: 136 0156 8070